Insulation Compactor

Compact Insulation

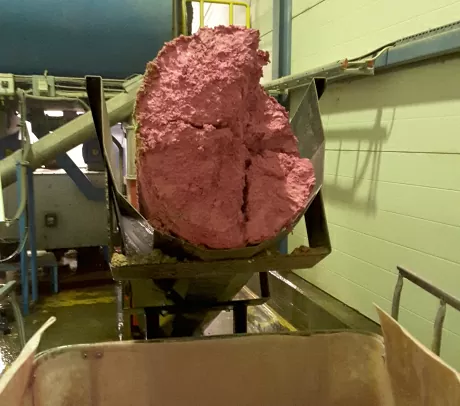

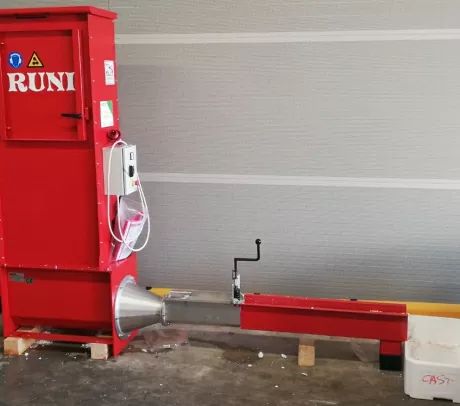

When disposal of insulation is necessary, a RUNI SK370 screw compactor can be used. The insulation compactor pre-crushes and compacts all forms of mineral wool (stone wool, glass wool, etc.) when introduced into the hopper of the machine. The machine pre-crushes and compacts the mineral wool into something similar to heavy sand, compacted directly into big bags. A full big bag weighs around 600-700 kg/m3

After compacting the mineral wool, it can be reused by casting it into concrete blocks, which can be useful for different companies. This way, we ensure the reuse of the mineral wool, so it doesn't just go to landfill, which is also a very costly solution.

RUNI Solution for Recycling Insulation

When the mineral wool is fed into the pre-crusher, it will be shredded. Afterward, the screw and the hydraulic jaws will automatically ensure that the material will be compacted into a material that feels like heavy sand and finally compacted into big bags.

The machine can be configured with a 45º hopper or be fed with a conveyor belt into the vertical hopper. The different integrated sensors ensure easy handling with automatic start- and stop functions, and the speed can be adjusted. We have also designed a solution integrated into a container, with feeding from outside. The compactor works continuously with the material, and the full big bags can be taken out of the end of the container.

Benefits:

- Reduce the cost of warehouse, transport, and disposal

- Reduce manual labor

- Safe and easy operation with automatic start and stop

Options:

- Design of solution in containers for companies or recycling stations

- Specially designed for demolition companies (connected to vacuum-suction)

- Remote control for quick troubleshooting and assistance from factory

The RUNI SK370 Function of Dewatering Wet Insulation:

RUNI has also delivered screw compactors for the dewatering of wet mineral wool, which could origin from:

- Nurseries. The nurseries' grow bags are full of water after use - here, the weight can be reduced by half or more.

- Filter material. Some industries use mineral wool as filter material. Used filters can be compacted and dewatered in a RUNI screw compactor for mineral wool and used for great benefits.

Jasar Recycling – Dewatering PET Bottles

Jasar Recycling Installed a New Runi SK370 Dewatering Compactor for their East Palestine, OH Location. Jasar Recycling uses a RUNI SK370 for dewatering of PET bottles with PET bottle recycling in mind. Here os what Ed McNee from Jasar Recycling says about the screw compactor from RUNI: “We are very happy with the RUNI SK370 PET dewatering system. Right now, we are running the machi...

Nen-Products - Beverage Cartons

Separation Leads to Savings on Waste Charges Separation and dewatering in connection with destruction of Tetra Pak cartons turned the waste dry enough for recycling. NEN-PRODUKTER AS in Norway produces juice and smoothies sold in various forms of Tetra-Pak cartons. “We have to take care of thousands of units every day due to normal and unforeseen production waste. A major part of this ...

Premier Patterns - EPS Compaction

Investment Paid Back Within 12 Months The SK120 meant great savings for small British industrial company. Even with RUNI's smallest screw compactor, waste is turned to value. At the same time, the company got rid of the mess of uncompacted EPS and dust. PREMIER PATTERNS AND CASTINGS LIMITED in the UK produces EPS patterns and moulds in all sizes, especially for the automotive, boat and aerosp...

Skjern Papir - Drying Reject from Paper Mill

Dewatered Waste Is Disposed at Lower Cost By compacting and dewatering reject, a paper recycling company avoid having to transport water for no useful purpose. SKJERN PAPIR A/S in Denmark produces 54,000 tons of liner and cardboard from recycled paper annually. In the initial sorting, the paper material is separated out from large, insoluble materials such as plastic, staples and other unwant...

Folldal Recycling - Drying PE film

Environmentally Friendly and Energy-Saving Drying of PE Film Folldal Gjenvinning saves between 100 and 150 kW/h per production line by pre-drying washed plastic film in a RUNI Screw Compactor. Folldal Gjenvinning, a division of Norfolier Norge AS, is one of Scandinavia’s largest recyclers of plastic film. With its latest production expansion, the division’s annual capacity ha...

Dan-Web - Dust Compaction

Well Suited for Dust and Waste Products from Airlaid Production Less dust, easier handling and reduced transport costs. The RUNI Screw Compactor represents a great advance in airlaid production waste management. Dan-Web in Aarhus produces machinery and equipment for the manufacture of airlaid products such as nappies, sanitary towels, bed sheets and meat pads – primarily as turn-key pro...

Carlsberg Breweries - Compaction of Aluminum Cans and PET Bottles

Dewatering Various Cans and Bottles with RUNI Screw Compactor Besides beer cans, Carlsberg Breweries in Denmark also produce Coca-Cola® in aluminum cans and PET-bottles. Carlsbergs effective quality control daily sorts out substantial quantities, that needs to be destroyed. For more than 15 years Carlsberg has used a RUNI SK370 for emptying and compacting of PET-bottles. A few yea...

Rexcell, Sweden - Airlaid

Compacting Airlaid Dust with Screw Compactor The Swedish company, Rexcell, produces tissue and airlaid. They are among the leaders within this business with a high level of technology in their production. The RUNI SK370 was installed under their extraction system to compact the dust before it goes into the waste container. The advantage with a RUNI screw compactor is the continuous operation ...

Systec, Germany - Plastic Film Recycling

Drying PE-Film with RUNI Screw Compactor One of the largest manufacturers of plastic granules from post-consumer waste in Europe, Systec Plastics Eisfeld GmbH in Germany, chose in 2017 to replace their existing installation of screw compactors with 6 new RUNI screw compactors type SK370, into their washing line for PE film, as part of the drying process of the crushed and washed plastic flakes...

Oyak, Turkey - Drying RDF

Drying RDF at a cement factory in Turkey For some years, the Turkish cement company OYAK CIMENTO had tried to find the optimal drying of their incoming RDF, which they use as alternative fuel at their cement kiln. In 2022, a trial was set up with a RUNI SK370Twin. The test showed a very satisfying result bringing the RDF down from above 50% moisture to below 30%. Together with the RUN...

Recycling Off-Cuts and Rejected Foams at Selit North America

For over 40 years, Selit North America has specialized in extruding the foam layer beneath the flooring commonly found in households, offices, or buildings. In their extrusion line, they generate off-cuts from trimming rolls of foam, as well as rolls generated during transitions between different foam types they produce. In Commerce, GA, EPE and XPS foam sheets are extruded, and Runi plays an...

Dust Compaction - PreZero

Compacting Dust From Demolition Waste Significantly PreZero is an international waste handling company with subsidiaries in many European countries. In Groningen, The Netherlands, PreZero receives demolition waste from buildings. Treating this waste creates significant volumes of dust. Until the RUNI-installation dust was extracted through a ventilation system and went through filters into...

Norlax - EPS Fish Boxes

Environment Friendly EPS Handling Turns Waste to Value Norlax earned a return on its investment in a RUNI SK370 and its housing within 2 years. On a good day, up to 1,000 boxes of salmon are fed into production at NORLAX A/S, Denmark. The huge quantity of EPS boxes used to fill 4 truckloads per day, which commuted constantly between the company’s premises and a waste handling company 30...

Vega Salmon - EPS Fish Boxes

Compacting Fish Boxes of EPS (Airpop) with Screw Compactor In 2011 VEGA Salmon built new production facilities in Northern Germany very close to the German –Danish border for processing salmon. The production level is characterized by high flow which requires a high capacity compaction unit. The traditional way of solving high capacity demands is to have a stand alone pre-crusher and a ...

North Landing - EPS Fish Boxes

The RUNI Screw Compactor Has Been Great North Landing, LLC of Clifton, NJ installed a new RUNI SK370 EPS compactor for densifying fish boxes into recyclable logs. The screw compactor is used for compacting the fish boxes into a dense block, minimizing the transportation costs and saving space in the warehouse. “The Runi compactor has been great. It has allowed us to keep our receiving d...

Morpol, Poland - Processor of Fresh Salmon

Compacting Used EPS Fish Boxes with Screw Compactor Morpol in Poland, for many years the world’s largest processor of fresh salmon and today part of the Marine Harvest group. Every day Morpol receives thousands of EPS boxes with fresh salmon and chilling ice. The boxes are only being used once and Morpol therefore uses the RUNI SK370 for effective handling of the empty wet boxes contamin...

Cap Fraicheur, France - EPS

Solution for EPS-handling with Screw Compactor Cap Fraicheur, a French retail chain with a large sale of fish was looking for a solution to compact their many used EPS fish boxes. Normally they have around 60 kg (130 lbs) per day. Most of the stores are located in city centers, and the available space is very limited. Besides the lack of storage, the odor from the used fish boxes was causing ...

O.H. Fiskeeksport - EPS Fish Boxes

You Don't Scrap an Old RUNI For 25 years, RUNI has supplied the European salmon industry with quality compactors to handle the EPS boxes in which the salmon factories receive their fresh salmon on ice. The industry has experienced growth, and companies who started out with one RUNI, has often had the need to upgrade to a higher capacity. During 2022, RUNI delivered several upgrades, including ...

Supermercati Tosano - EPS fish boxes

EPS Compactors: the efficient and sustainable choice of Supermercati Tosano Supermercati Tosano, an Italian family-run supermarket chain founded in 1970, has found an intelligent solution to manage the growing quantities of expanded polystyrene (EPS) waste generated by its stores. With 19 stores mainly present in the Veneto region but expanding throughout Northern Italy, Supermercati Tosano is...

Rooms To Go - EPS Packaging

Waste Management Creates Profit Large US furniture chain turns over USD 3 million through recycling of packaging In 2007, the US furniture chain Rooms To Go turned over USD 1.75 billion worth of furniture – products packaged using vast amounts of cardboard, wood, plastic and EPS. But already in 1991 the chain introduced a recycling programme that has transformed waste into a profitable ...

Chantry Digital - EPS Electronics

Storage Handling Would Be Difficult Without the RUNI SK120 RUNI SK120 has meant tremendous savings for a British retailer, in terms of both space and money. CHANTRY DIGITAL is a British retailer within consumer electronics and hard electrical appliances. The company covers four counties with seven outlets, and has a large nationwide commercial division. At its head office in Trowbridge, Chan...

Multiple Benefits from Compacting EPS

Xerox is a household name in the world of office equipment and printing. When it comes to shipping valuable electronics or equipment, such as Xerox’s commercial printers and copiers, EPS packaging is an unparalleled solution with its low weight and impact-resistant properties. However, after delivery, two problems become present with the discarded packaging: it takes up significant ware...

Veglo - Metal Cans

Separating Paint Leftovers from Buckets By separating paint from the buckets and compacting the packaging, the waste handling company saves money on both transport and disposal. Efficient Paint Waste Management with VEGLO MILJØSERVICE AS VEGLO MILJØSERVICE AS is dedicated to collecting and processing hazardous waste from companies across a wide geographic area in central Norway...

Silkeborg Recycling Station

Optimises Recycling of EPS (Airpop) with Reason Approx. 30 tons annually or equivalent to more than 60 truckloads of EPS are collected today instead of going into the container with other combustible materials. The EPS has previously been a large part of the combustible fraction, but is now compacted on site and sold for recycling with reduced transport costs. The 30 tons of compacted EPS blo...

Haith Recycling, Great Britain - Biogas Industry

Optimize Biogas Production with Screw Compactor Food waste is very suitable for anaerobic digestion plants. By separating as much of the organic liquid from the packaging the more feed stock is created for the plant and the weight of the packaging is reduced. The packaging normally goes to landfill. Haith Recycling searched the market before deciding upon a RUNI screw compactor. They fo...

Tarm Recycle Station - EPS

Compacting of EPS/airpop for recycling Tarm recycle station compact the gathered EPS, also known as airpop, in the recycle station with a RUNI SK200Twin and sells the compacted EPS blocks for recycling.Earlier the EPS was part of combustibles assorted, but now has to be separated. It has been quite a change for the citizens having to sort it and place it in a different place in the recycle sta...

Vartdal Plast - Compacting EPS

Vartdal Plast – takes the lead role in Norway From fish box producer to waste collector and LOOP ambassador Vartdal Plast is one of the biggest EPS converters in Norway and even in the Nordic region. The company was founded in 1962 and was, actually, the first company to produce fish boxes from EPS (Expandable Polystyrene). Keeping food fresh and houses warm is the very foundation of V...

Waste disposal - Dust

COMPACTING DUST TO PREVENT HARMFUL WORKING ENVIRONMENTS The RUNI SK370 compaction system has been installed as a capture element and transportation of the dust discharge of an extraction system at a German waste disposal company that sorts waste and recycles raw materials. The RUNI compactor is sealed, which makes it perfect for this purpose. The dust will be trapped inside the compactor unt...

Langage AD - Optimising biogas production

Langage AD, a leading producer of ice creams, yogurts, and clotted cream in Devon, UK, also operates an anaerobic digestion (AD) plant to process their waste food. The plant produces electricity for their factory and fertiliser for their land, creating a closed-loop production system. The presence of packaging materials like cardboard and plastics in the food waste posed a challenge, as disp...