Efficient Dewatering of Reject

Optimize Waste Management in Anaerobic Digestion Plants: Efficient Reject Handling

Biogas plants are key players in transforming organic waste into renewable energy. However, managing rejects such as plastic packaging and non-organic materials can be costly and inefficient. These wet rejects are heavy, difficult to transport, and challenging to dispose of, often trapping valuable organic material that could otherwise be turned into energy.

Effective waste management is key to minimizing costs, improving efficiency, and extracting maximum value from food waste rejects.

The Challenges of Handling Rejects in Anaerobic Digestion Plants

| Challenges | RUNI's solution |

| High Transport Costs: Wet rejects are heavy, making them costly to move. | Reduces weight by up to 55% through efficient dewatering, significantly cutting transport and disposal expenses. |

| Suboptimal Biopulp Yield: Organic material often remains trapped in rejects. |

Extracts extra biopulp for anaerobic digestion, increasing renewable energy output. |

| High Wear and Tear: Abrasive elements like sand or metal strain machinery. | Robust screws with hard metal construction and extensive know-how ensure reliable 24/7 performance and long operational life. |

| Space Limitations: Wet waste creates difficulties for storage. | Compacting reduces the volume of the reject by up to a factor of 3 and leaves a more clean storage area.. |

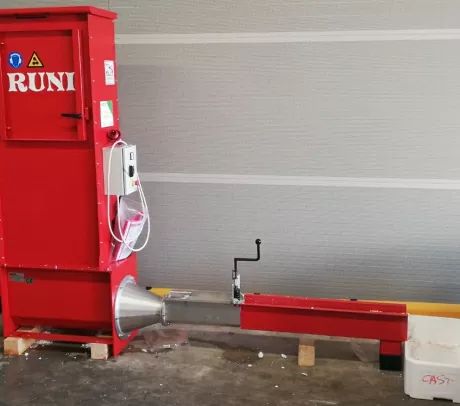

RUNI screw compactors are not only highly efficient but also designed for durability, offering long-term economic benefits. With minimal maintenance requirements and high-quality construction, they provide a cost-effective solution that pays for itself quickly.

Improve Biogas Production with Effective Dewatering of Rejects

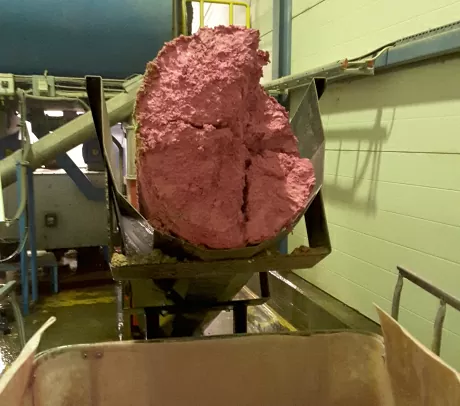

RUNI screw compactors are designed to efficiently handle biogas plant rejects, separating liquids from solids in a seamless process. The process works by feeding wet rejects—such as food waste packaging or other non-organic materials—into the RUNI screw compactor. Here, the screw compresses the material under high pressure, extracting the liquid (organic biopulp) for reuse in anaerobic digestion while leaving reject with a much higher dry matter content ready for easier disposal or transport.

With RUNI screw compactors, biogas plants can streamline their operations, reduce costs, and achieve a more efficient energy production.

The RUNI Advantage: Dewatering Solutions for AD Reject

RUNI’s screw compactors are designed to meet the needs of anaerobic digestion plants, delivering significant advantages:

Enhanced Biopulp Recovery: Extract more valuable organic material for increased biogas output.

Durability and Long-Term Value: RUNI machines are built to last, with robust construction, stainless steel components, and hard metal screws that ensure minimal downtime and extended operational life. With a competitive Total Cost of Ownership, these machines quickly pay for themselves and continue to deliver economic benefits for many years. A 24-month warranty provides peace of mind from the start.

Minimal Manual Labor: Automation options, such as sensors for automatic start/stop, ensure seamless operation with minimal effort.

Customizable Solutions: Modular design ensures seamless integration with your existing systems, and give you the flexibility of adapting or upgrading the machine, if your needs change over time.

Proven Performance: Trusted worldwide for reliable dewatering and compacting solutions. 24/7 performance with capacity ranging from 2,000 to 5,000 kg per hour, depending on the chosen model.

Remote Access, BUS-Communiction and Service: Machines are equipped with remote access capabilities for efficient troubleshooting worldwide. If on-site service is required, our technicians or our extensive distributor network are ready to assist promptly. Additionally, the machines can be equipped with BUS modules for integration into existing SCADA systems.

Here you can read more about how Langage AD optimized their biogas production with a RUNI SK370.

If your plant receives large quatities of liquids from the food industry, that needs to be destraoyed, we also offer solutions for that purpose. This means you can bypass your depacker. Read more about our solutions for product destruction here.

Optimize Your Biogas Plant Operations Today!

Contact us today to learn how our solutions can enhance your waste management process, protect your brand and turn inevitable waste to value.