Efficient Product Destruction at Dairies - Dewatering of Yogurt Tubs and Milk Cartons

Efficient Waste Management in Dairies: Destruction of Yogurt Tubs, Milk Cartons, and Tetra-Pak

Even with high-quality control in dairy production, defective, returned, mislabeled, or expired products will arise. Whether due to overproduction, quality issues, or expired goods, dairies require solutions that efficiently handle diverse packaging types like Tetra-Pak, PET bottles, and yogurt tubs, etc.

Managing this waste effectively is not just about disposal—proper waste management is essential for reducing costs, safeguarding brand reputation, and meeting environmental responsibilities in today’s market.

The Challenges of Waste Management in Dairies

| Challenges | RUNI's Solution |

| Storage Issues: Defective products take up valuable storage space. | Compacts waste significantly, reducing volume and handling costs. |

| Brand Protection: Improperly destroyed products can be resold or consumed, damaging the brand's reputation. |

Guarantees 100% destruction of dairy products and packaging. |

| High Disposal Costs: Transporting liquid-filled products to incineration is expensive due to weight, volume and the low burning value of the liquids. | Generates two waste streams: Separated liquids can be used for biogas or animal feed. Compacted packaging can be sold for recycling or sent to incineration at a much lower cost. |

| Environmental Responsibility: Ensuring a more eco-friendly handling of waste products is a growing demand from both regulatory authorities and consumers. | Facilitates recycling of both liquids and packaging. |

RUNI’s Solution for Destroying and Dewatering Dairy Products

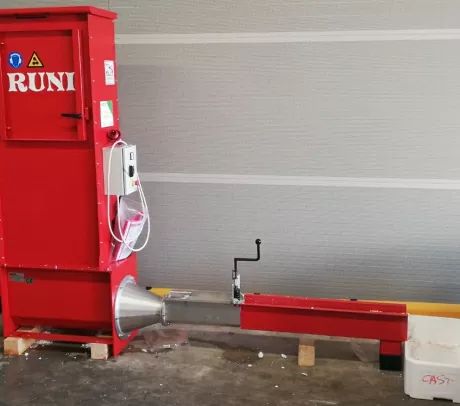

RUNI offers screw compactors designed to efficiently handle defective products, reduce costs of storage and disposal, and turn waste into value.

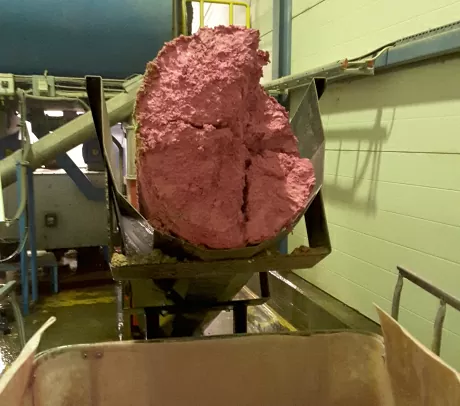

Our machines work by separating packaging from its contents in a single, continuous process requiring minimal manual labor. This generates two distinct waste streams: dry, compacted packaging and collected liquid, both of which can be reused or recycled.

- Separation: The liquid content is pressed out and collected, ensuring the packaging is dry.

- Compaction: Packaging is compacted, reducing volume significantly.

- Reuse: Separated liquid can be used for biogas production or animal feed, while the packaging can be recycled or cost-efficiently incinerated.

Why Choose RUNI for Dairy Waste Management?

- Proven Efficiency: The SK370 separates up to 5,000 kg of dairy products per hour

- Proven Durability with Low Maintenance Costs: RUNI machines are built to last with robust construction, stainless steel components, and hardened metal screws that ensure minimal downtime and long operational life. Their efficiency, durability and low maintenance costs allow the machines to quickly pay for themselves, providing economic benefits for years to come. All machines come with a two-year warranty for added peace of mind.

- Custom Solutions: Customizable infeed and exit chutes to fit specific needs. And if your needs change, the machine can be upgraded or modified without requiring a full replacement.

- Ease of Use: Equipped with sensors for automatic start/stop and compatible with feeding screws or tip containers, RUNI compactors require minimal manual labor. With a feeding screw, the RUNI SK370 can even process whole pallets of material for separation.

- Remote Access and Global Support: With remote access, RUNI technicians can troubleshoot issues online. If necessary, on-site support is available worldwide through our extensive distributor network.

- Sustainability Focus: Ensures recycling of both liquids and packaging, turning waste into value.

By implementing a RUNI screw compactor, dairies can reduce costs related to storage, transport, and disposal while enhancing the recyclability of their waste.

Ready for an Efficient Solution for Destroying, Dewatering and Compacting Liquid Dairy Products?

Contact us today to learn how our solutions can enhance your waste management process, protect your brand and turn inevitable waste to value.