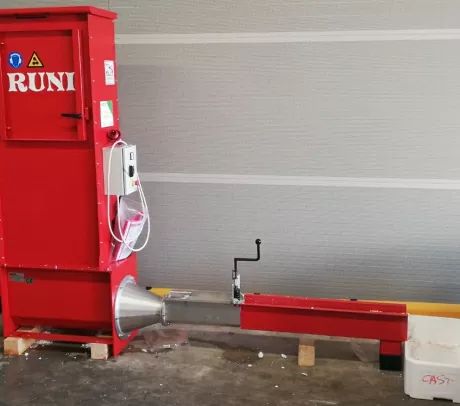

RUNI SK370 Screw Compactor - Compaction

Compactor for Great Quantities of Trash

The SK370 screw compactors are RUNI's largest machines for compacting EPS, EPP, EPE, XPS and PUR. We recommend this size for an annual volume of more than 50 tonnes.

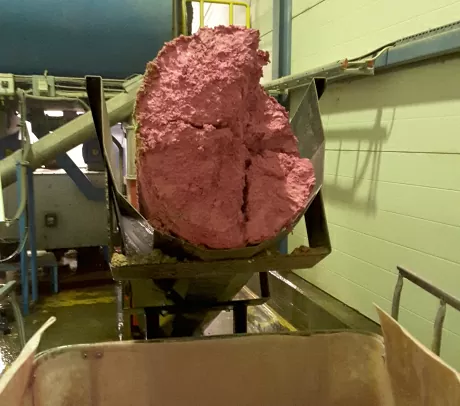

The SK370 screw compactor can compact EPS (also known as airpop) at a ratio of up to 50:1. This means that 50 truckloads of uncompacted EPS can be replaced by one truckload of compacted EPS. The density of the compacted blocks of EPS, EPP, and XPS is approx. 350 kg/m³, and 600 - 750 kg/m³ for EPE. The compacted blocks can be stacked on a pallet and sold for recycling. A truck or container can load approx. 20 tonnes.

For PUR, the SK370 can also achieve a density of 350 kg/m³, but PUR cannot form a cohesive block and must be compacted into bags.

The SK370 can be fed manually into a 45° hopper or by conveyor belt into a vertical hopper. The foam is pre-crushed in the hopper and the screw, and the automatic hydraulic jaws compact the foam to solid and uniform blocks. The density and size of the foam are crucial for the choice of pre-crusher. The different incorporated sensors ensure easy operation with the automatic start and stop function and adjustable speed.

Twin models with two or three screw compactors ensure even higher efficiency for customers handling large volumes of foam. It is also possible to place the compactor below a silo and buy an automatic block divider and crane for handling the compacted blocks.

Benefits of the SK370 Model:

- Larger screw, more power, more capacity

- Profit from converting waste to reusable material

- Save space and handling costs by processing waste quickly and efficiently

- Save energy – no added heat required for most of the materials.

- Different configurations for a large number of materials

- Reduce manual labour

- Safe and easy operation with sensors for automatic start and stop of the machine

Various Options:

- Heavy Duty Pre-crusher can be fitted for particularly tough and dense materials

- Pre-crusher is available in different configurations and motor sizes

- Twin models with multiple screw compactors

- Silo solution

- Automatic block divider and crane for handling the compacted blocks

- A melting unit to melt the outer surface of some materials that are prone to re-expansion

- Remote control

The SK370 Screw Compactor is a big, heavy-duty, and versatile machine that compacts a large variety of different materials, including those that have made other machines stop working.

The RUNI SK370 can be fitted with an extensive range of accessories: various feed hoppers for manual or automatic feeding, conveyor belts, silo systems, automatic block divider, cranes, etc. It can also be fitted with a perforated matrix if wet foam needs to be dewatered.

RUNI also develops and supplies customized solutions as required.

Power consumption

Main motor: 15,00 kW

Hydraulic pump: 0,55 kW

Pre-crusher motor: 1,10 kW or 5,50 kW

Hourly Capacity

The SK370 machine can compact up to 200 kg EPS (about 300 fish boxes with lids), EPP, EPE, PUR or XPS per hour. The higher the density of the material, the lower the capacity of the machine.

Warranty

As with the SK200 and SK240, we offer a 2-year warranty or 6000 operation hours, whichever comes first for the machine.