Recycling Machinery - About Screw Compactors

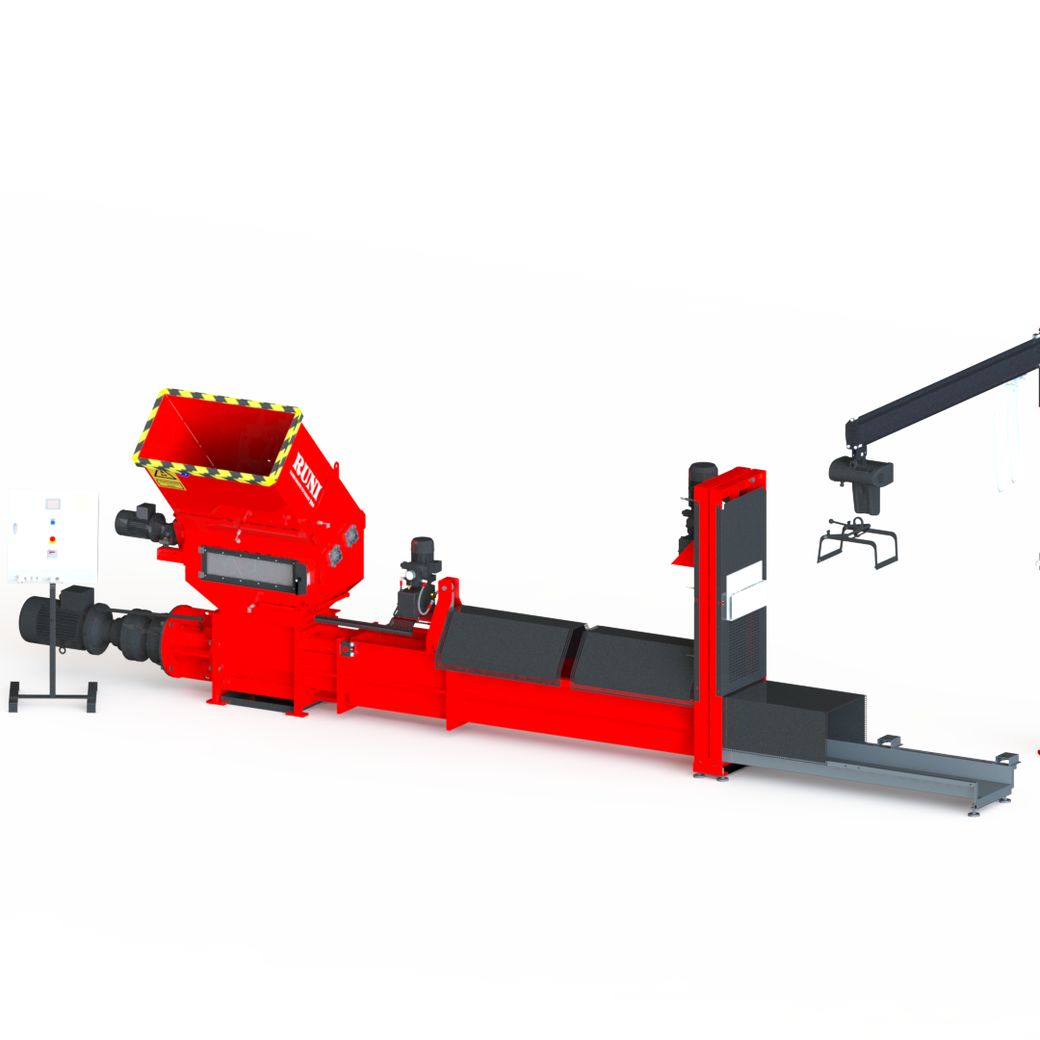

RUNI Screw Compactors – efficient, tailored, and robust. Compress diverse materials, separate liquids from solids, and integrate seamlessly into your production line. High pressure, low energy, minimal handling – designed for tough jobs and maximum output.

Recycling Machinery - About Screw Compactors

RUNI Screw Compactors – efficient, tailored, and robust. Compress diverse materials, separate liquids from solids, and integrate seamlessly into your production line. High pressure, low energy, minimal handling – designed for tough jobs and maximum output.

Screw compactors have two main purposes:

They can compact many different kinds of material quickly and effectively, e.g., EPS boxes used in fish boxes in the seafood industry

They can separate liquids from solids, e.g., water from washed plastic

Often, both characteristics are explored at the same time. For example, when emptying and compacting juice cartons.

Recycling machinery customized for the purpose

Runi Screw Compactors has a basic unit, which is available in three sizes and used in all machines. In addition, there are also standard or customized accessories, which make the machine particularly suitable for the specific job it performs.

The primary aim is always to customize the compactor to ensure it suits the customer's existing production facility as much as possible. At the heart of the machine is a hydraulic-automatic feed-control system, which ensures uniform compacting for all materials at all times without overloading the compactor.

Minimal handling

The large capacity of the Screw Compactor, and its slim-line design, make it well suited for locating directly in a process line or at the end of a production line to minimize handling. Start and stop can be controlled in many ways, either manually or automatically, using sensors. A fully automatic, hydraulic Silo System with a Heavy Duty Pre-crusher and several large screw compactors can cope with enormous quantities without having an operator between the separation and final compacting processes.

The great advantages of Screw Compactors:

- Optimum solutions based on RUNI’s pioneering work, development, and long experience

- Continuous compacting of material

- High rate of compacting because of high pressure

- Low energy consumption because of the torque of the screw

- No heat is required; instead, the friction of the material is used, saving energy

- Tough and user-friendly, built for hard work

Case Studies

At Carlsberg in Fredericia, RUNI compactors empty and compact PET bottles, aluminum cans, and plastic kegs – efficiently and reliably.

Read more

One of Europe's largest producers of plastic granulate from consumer waste chose in 2017 to replace their existing installation of screw compactors with 6 new RUNI screw compactors of the SK370 type.

Read more

Every day, Morpol receives thousands of EPS boxes containing fresh salmon and cooling ice. The boxes are used only once, and therefore Morpol uses the RUNI SK370.

Read moreContact Us

If you need more information or have questions about RUNI products, please fill out the form below. We will get back to you as soon as possible.

Learn more about our privacy and cookie policy.

Contact US Office

+1 (630) 422-3172

runi-us@runirecycling.com

351 Country Club Drive,

Bensenville, IL 60106