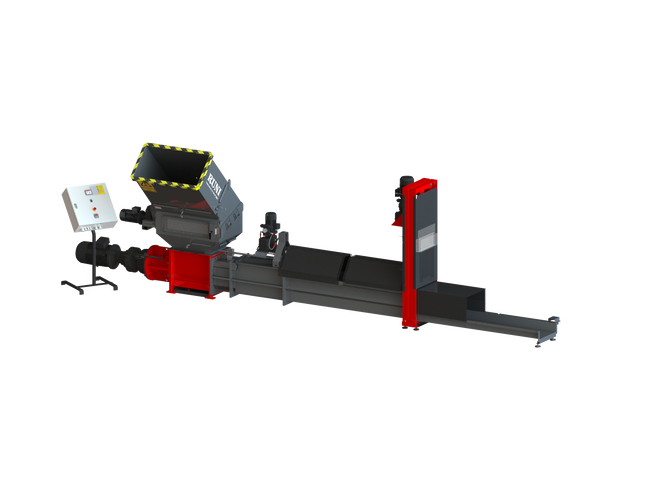

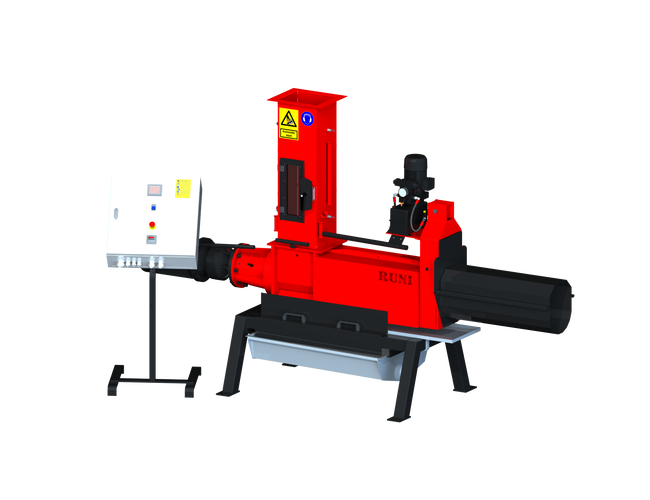

RUNI SK240 Screw Compactor -Separation

From packaging and production waste to rejects and labels – the RUNI SK240 handles a wide range of materials. It separates liquids and solid materials in one operation, making the waste dry, easier to handle, and ready for cheaper disposal or recycling.

RUNI SK240 Screw Compactor -Separation

From packaging and production waste to rejects and labels – the RUNI SK240 handles a wide range of materials. It separates liquids and solids in one single process, leaving the waste dry, easier to handle, and ready for more cost-effective disposal or recycling.

The Screw Compactor for Dewatering of a Wide Range of Materials

RUNI SK240 screw compactor is the smallest of the RUNI machines that can dewater and separate solids from liquids. The SK240 can dewater expired or wrongly labeled products or any other products that require destruction for whatever reasons. These products include aluminum cans, PET bottles, Tetra-Pak, cosmetics, etc.

When the machine separates, compacts, and creates two waste streams in one continuous process, the liquid is pressed out through a matrix and can go directly into the drain or (if edible) be collected and used for animal feed or sent to anaerobic digestion plants for the production of biogas. The compacted packaging material is slowly pushed out of the exit chute and can easily be collected in containers. After compacting, the packaging becomes so dry that it can be sent to incineration at a lower cost or sold for recycling. Installing the compactor close to the production area helps increase the certainty of carrying out the destruction. It saves costs on manual handling, storage, and transportation.

The SK240 is suitable for drying rejects from plastic washing plants and dewatering wet stickers and labels. Anaerobic digestion plants can also benefit from the SK240 as it can dewater the reject from food waste and squeeze out extra biomass for the pulper. Dewatering the reject with a RUNI SK240 makes the reject dry enough for incineration instead of ending up as an expensive and polluting waste at a landfill.

TURN WASTE TO VALUE!

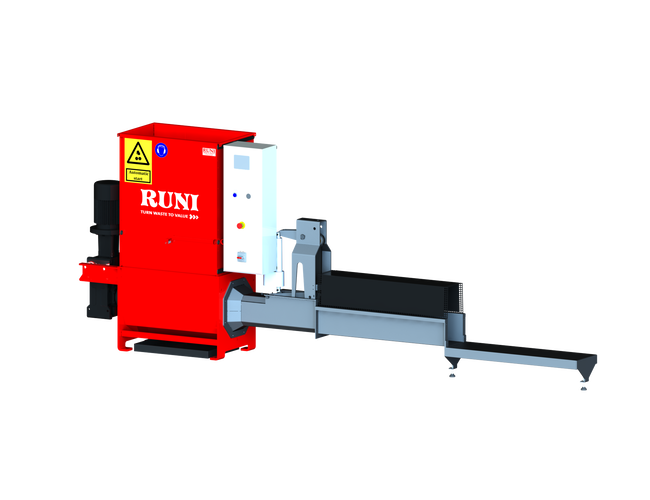

Which Machine to Choose?

The RUNI screw compactors for dewatering come in two different sizes: The SK240 and the SK370. Which to choose depends on the capacity needed and the size of the material.

The SK240 is suitable for handling packaging sizes up to 1 liter. It can dewater 7.000 aluminum cans containing 33 cl, 5.000-litre Tetra-Pak, or 5.000 0,5 liter PET-bottles.

With the SK240, the following densities of these compacted packaging materials can be reached:

- Alu cans: 400 kg/m3

- Tetra-Pak®: 500 kg/m3

- PET-bottles: 225 kg/m3

The same machine can dewater different materials, but they must be sorted before entering the RUNI if you want to sell the dry packaging for recycling.

The SK240 is available with a standard vertical hopper or conical hopper. Customized hoppers can also be made. The compactor can be fed manually, via a conveyor, or with a tip-container.

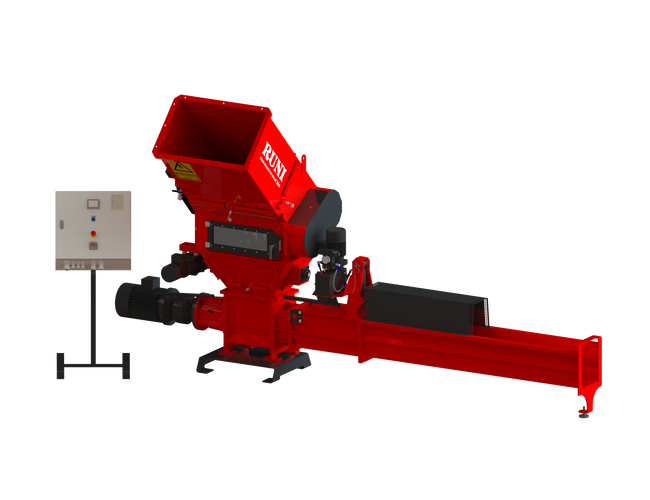

Benefits of the SK240:

- Easy destruction of faulty or expired products. The machine separates and compacts in one continuous flow.

- Save space and handling costs through rapid and efficient waste management.

- Compaction rate of PET bottles: 8:1.

- Compaction rate of aluminum cans: 20:1

- Profit from selling separated liquid and compacted packaging.

- Decreasing costs associated with bringing rejects to landfill, as they can now be sent to incineration with a much lower water content. The weight of the waste is also reduced, decreasing the transportation costs.

- The amount of manual labor associated with handling the waste can be reduced.

Power consumption

Main motor: 5.5 kW

Hydraulic pump: 0.55 kW

Hourly Capacity

Alu cans: 7.000 pcs. 33 cl. cans

Tetra-Pak®: 5.000 l.

PET bottles: 5.000 pcs. 0,5 l. bottles

Max. size: 1 l.

Paper labels: 1500 kg

Plastic labels: 400 kg

Reject from plastic washing plant: 1500 kg

Reject from refining food waste: 500 – 1000 kg

Warranty

As with the SK200 and SK370, we offer a 2-year warranty or 6000 operation hours, whichever comes first for the machine.

RUNI SK120

Our smallest EPS compactor, suitable for retail and small industrial businesses. It has a capacity of approx. 18 kg per hour and is typically fed manually. It is recommended for an annual volume of less than 10 tons per year. It is available with either automatic or manual jaws.

Read more

RUNI SK200

Our second smallest compactor has a capacity of approximately 45 kg per hour and is typically fed manually. It is recommended for an annual volume of 10 to 30 tons. It is available with either automatic or manual jaws.

Read more

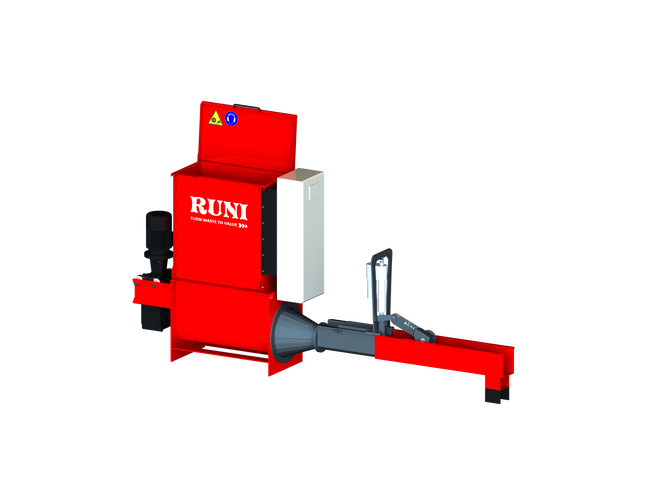

RUNI SK240 - Compaction

The RUNI SK240 screw compactor is the second largest in the RUNI range. It is capable of compacting a wide variety of materials, with capacity and output depending on the specific input.

Read more

RUNI SK240 - Separation

The SK240 is our smallest dewatering machine. Capacity and output depends on the application. The machine can dewater cans, plastic bottles, and Tetra Pak, as well as dry various wet fractions such as rejects and washed PE film.

Read moreCase Studies

Filling of various cans and bottles with RUNI screw compactor. In addition to beer cans, Carlsberg Breweries in Denmark also produces Coca-Cola® in aluminum cans and PET bottles.

Read more

At Langage AD in Devon, UK, reject from the biogas plant is dewatered and compressed with up to 60% liquid reduction. The result is lower weight, reduced volume, and significant savings.

Read moreContact Us

If you need more information or have questions about RUNI products, please fill out the form below. We will get back to you as soon as possible.

Learn more about our privacy and cookie policy.

Contact US Office

+1 (630) 422-3172

runi-us@runirecycling.com

351 Country Club Drive,

Bensenville, IL 60106