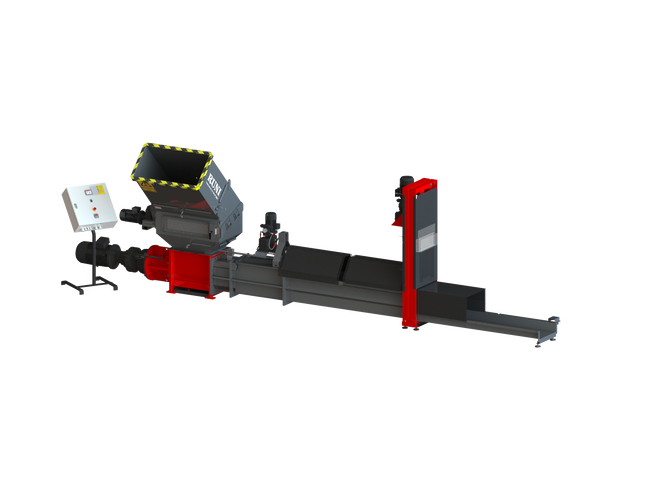

Compactor for Great Quantities of Trash

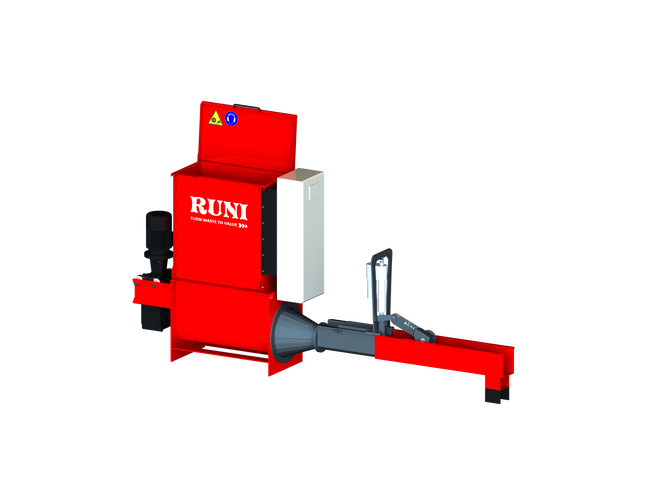

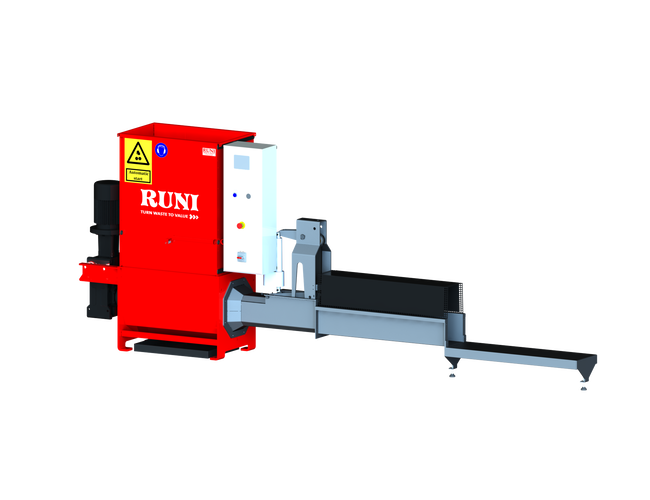

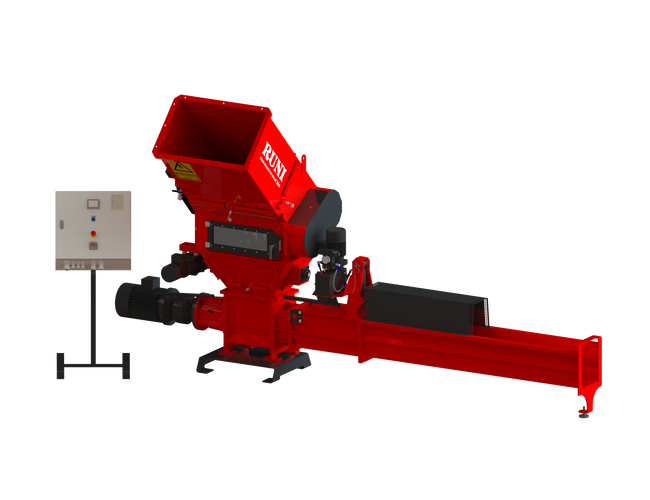

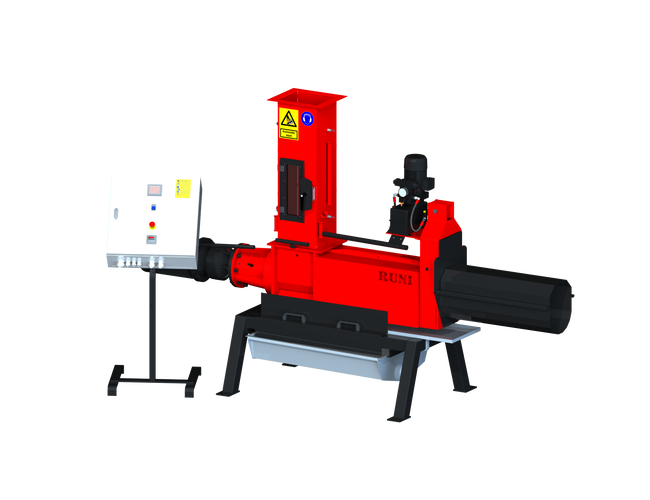

The SK370 screw compactors are RUNI's largest machines for separating solids from liquids, and they can dewater various products.

The SK370 is the optimal solution for drying LDPE-film after washing. Using only 20 KW to dry 1 ton of PE-film (the SK370 reaches a moisture content of 5-10% in PE-film), the SK370 is very energy efficient, and often the machine has a quick ROI, as plastic recycling plants can save a huge amount of electricity compared to traditional drying methods.

The SK370 can also be used for drying RDF, which can lower the moisture content from above 50% to below 30 % (depending on the material mix) and increase the calorific value significantly.

Anaerobic plants can also benefit from the SK370. The machine can dewater the rejects from food waste and squeeze out even more biopulp for biogas. Simultaneously, the weight of the reject is reduced, making it cheaper to dispose of and leaving it dry enough to be sent for incineration.

The SK370 can also be used for product destruction at dairies, breweries etc. It can dewater and compact PET-bottles, aluminum cans, Tetra-Pak, and other packaging in one continuous flow. The liquid comes out at the bottom of the machine and can be collected for either animal feed or biogas. The empty and compacted packaging comes out at the end and can be sold for recycling or sent to incineration.

TURN WASTE TO VALUE!

Benefits of the SK370 Model:

- Larger screw, more power, more capacity

- Profit from converting waste to reusable material

- Save space and handling costs by processing waste quickly and efficiently

- Save energy – the machine is very energy efficient

- Different configurations for a large number of materials

- Reduce manual labour

- Safe and easy operation with sensors for automatic start and stop of the machine

Options:

- Multi-machine models available with multiple screw compactors for very high capacity

- Big version available for dewatering packaging containers larger than 5-10 liters

- Remote control

The SK370 Screw Compactor is a big, versatile machine that dewaters a large variety of different materials, including those that have caused other machines to give up.

The RUNI SK370 can be fitted with an extensive range of accessories: various feed hoppers for manual or automatic feeding, conveyor belts, exit chutes, consoles, and collection trays that fit the individual needs of every customer.

Power consumption

Main motor: 15 kW

Hydraulic pump: 0.55 kW

Hourly Capacity

The hourly capacity varies greatly from material to material:

LDPE-film: Min. 400 kg-Max. 800 kg

RDF: up to 5 tonnes

Reject from paper mills: up to 5 tonnes

Reject from refining food waste: 2-5 tonnes

Alu cans: 20.000 pcs. of 33 cl. cans

Tetra-Pak®: 15.000 liter

PET bottles: 20.000 pcs. 0,5 liter bottles or 8.000 pcs. 1,5 liter bottles

Warranty

As with the SK200 and SK240, we offer a 2-year warranty or 6000 operation hours, whichever comes first for the machine.

RUNI SK120

Our smallest EPS compactor, suitable for retail and small industrial businesses. It has a capacity of approx. 18 kg per hour and is typically fed manually. It is recommended for an annual volume of less than 10 tons per year. It is available with either automatic or manual jaws.

Read more

RUNI SK200

Our second smallest compactor has a capacity of approximately 45 kg per hour and is typically fed manually. It is recommended for an annual volume of 10 to 30 tons. It is available with either automatic or manual jaws.

Read more

RUNI SK240 - Compaction

The RUNI SK240 screw compactor is the second largest in the RUNI range. It is capable of compacting a wide variety of materials, with capacity and output depending on the specific input.

Read more

RUNI SK240 - Separation

The SK240 is our smallest dewatering machine. Capacity and output depends on the application. The machine can dewater cans, plastic bottles, and Tetra Pak, as well as dry various wet fractions such as rejects and washed PE film.

Read moreCase Studies

At Carlsberg in Fredericia, RUNI compactors empty and compact PET bottles, aluminum cans, and plastic kegs – efficiently and reliably.

Read more

When Systec Plastics Eisfeld replaced their screw presses with six RUNI SK370 auger compactors in the washing line for PE film, the result was a significantly lower energy consumption and 50% less moisture in the plastic flakes.

Read more

At Langage AD in Devon, UK, rejects from the biogas plant are dewatered and compressed with up to 60% liquid reduction. The result is lower weight, smaller volume, and significant savings.

Read moreContact us

If you need more information or have questions about RUNI products, please fill out the form below. We will get back to you as soon as possible.

Read more about our privacy and cookie policy.

Contact US Office

+1 (630) 422-3172

runi-us@runirecycling.com

351 Country Club Drive,

Bensenville, IL 60106