Optimize Food Waste Recycling by Dewatering

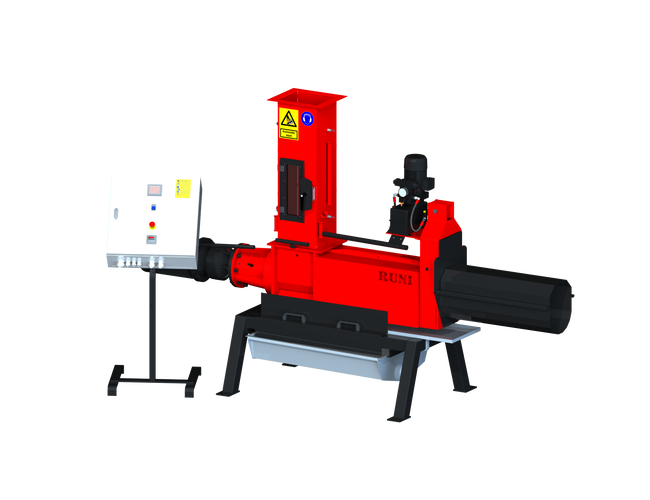

With a RUNI SK370 screw compactor, biogas plants can reduce the weight of wet rejects by over 50%, extract extra biomass, and significantly save on transport and disposal – a solution that both boosts efficiency and strengthens the economy.

Recycle Food Waste into Biopulp

A bigger part of household waste can be recycled and used as organic "energy soup" (bio-pulp) for degassing at biogas plants. The "energy soup" from food waste is used to create sustainable energy. The technology to separate waste from food and organic material is developing to provide the best possible solution and optimize production at biogas plants.

To be able to refine the organic part of the household waste, it is sent through a system where large amounts of water are added to separate the organic material from plastic and other materials. After the process, the plastic rejects, and other non-organic materials are left as a waste product with high water content. The wet rejects are expensive to transport, dispose of, or send to incineration, and RUNI has the solution.

Dewatering Food Waste with RUNI Screw Compactor

The installation of RUNI SK370 as a food waste compactor or as a machine for depackaging food waste reduces water content significantly, reducing the weight of the waste by more than 50%. Furthermore, a few extra percent of the organic material is collected from the waste and can be added to the "energy soup" for the biogas.

Producers of biopulp from food waste optimize their plants significantly with this solution, as they can reuse the dewatered water in their system and save money on transport and disposal of the remaining waste. Dewatering food waste also reduces both the volume and weight of rejects, saving you money on transportation and disposal.

The RUNI Solution for Food Waste

The RUNI SK370 screw compactor has proved to be a strong and reliable machine for many years. It is designed to work 24/7 with a capacity of processing 2000 kg of food waste rejects per hour. When dewatering rejects from food waste, RUNI typically achieves up to 50-65 % of dry matter.

FAQ

How does a food waste compactor work?

When handling food waste, the compactor squeezes the bio-liquid out of the reject to gain as much biogas as possible from the food waste. In the process, it significantly reduces water content, cutting the weight by over 50%. Operating continuously, it processes up to 2000 kg of food waste rejects per hour, optimizing biogas plant efficiency by minimizing water content, waste weight, and associated costs while maximizing bio-pulp output.

Is there any food waste you can not put in a compactor?

The food waste compactor handles liquefied food waste, usually together with packaging or plastic bags.

Case Studies

At Haith Recycling in England, the RUNI SK370 has proven to be the most effective solution for dewatering food packaging. The result is more organic liquid for the biogas plant and significantly lighter residual waste for disposal.

Read more

At Langage AD in England, a RUNI SK370 ensures that liquid is pressed out of packaging-containing food waste. The result is lower disposal costs, stable operation of the biogas plant, and a stronger circular economy.

Read moreContact Us

If you need more information or have questions about RUNI products, please fill out the form below. We will get back to you as soon as possible.

Learn more about our privacy and cookie policy.

Contact US Office

+1 (630) 422-3172

runi-us@runirecycling.com

351 Country Club Drive,

Bensenville, IL 60106