EPS Styrofoam Densifier / Compactor

EPS waste can be compacted at a ratio of 50:1 with our RUNI styrofoam compactor. If 50 trucks were needed to transport the EPS waste to landfill before compaction, only one truck will be required after compaction. The compacted blocks can be stacked on a pallet and sold for EPS recycling. Approximately 20 tons of EPS blocks can be loaded onto a truck or into a container.

EPS Styrofoam Densifier / Compactor

EPS waste can be compacted at a ratio of 50:1 with our RUNI styrofoam compactor. If 50 trucks were needed to transport the EPS waste to landfill before compaction, only one truck will be required after compaction. The compacted blocks can be stacked on a pallet and sold for EPS recycling. Approximately 20 tons of EPS blocks can be loaded onto a truck or into a container.

Turn EPS Waste into Value with a Styrofoam Densifier

EPS is better known under other names, such as airpop or styrofoam. This versatile material serves various purposes, from insulation to protecting products during transportation. The light but expansive material is not biodegradable, and when not compressed, it often ends up in landfill, creating significant problems. However, by selling compacted EPS blocks, you can generate an income. Hence, compacting the EPS creates a win-win situation for your business and the environment.

EPS foam compaction for Recycling

Our RUNI styrofoam densifier has an energy-efficient design, distinguishing it from other styrofoam densifier manufacturers. Unlike other manufacturers of styrofoam densifiers, the RUNI styrofoam densifier does not add any additional heat to the process; instead, the EPS waste generates the necessary heat through friction.

RUNI SK120

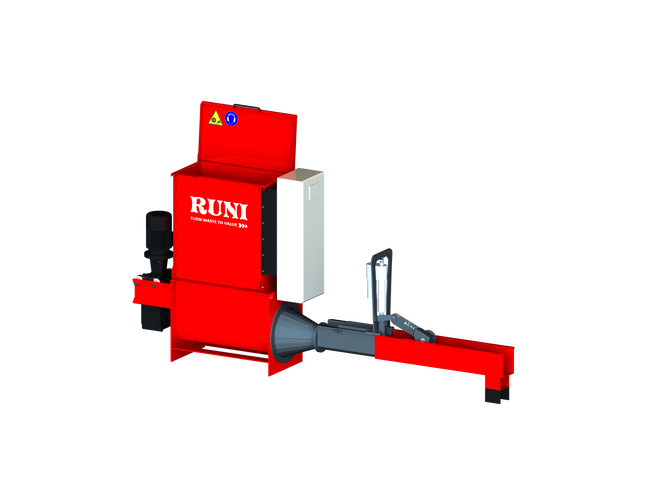

Our smallest EPS compactor, suitable for retail and small industrial businesses. It has a capacity of approx. 18 kg per hour and is typically fed manually. It is recommended for an annual volume of less than 10 tons per year. It is available with either automatic or manual jaws.

Read more

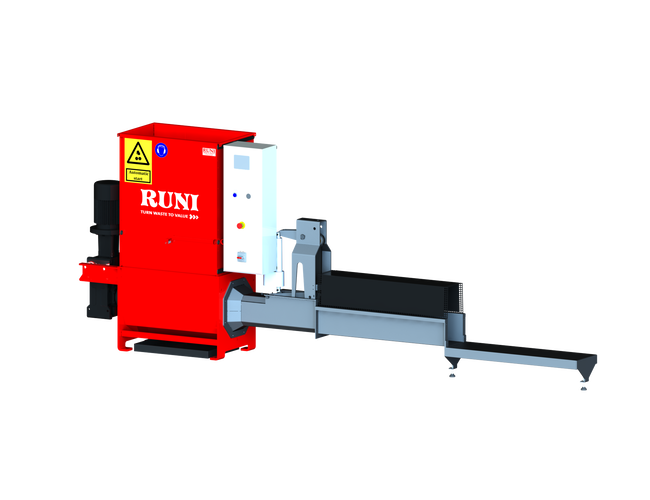

RUNI SK200

Our second smallest compactor has a capacity of approximately 45 kg per hour and is typically fed manually. It is recommended for an annual volume of 10 to 30 tons. It is available with either automatic or manual jaws.

Read more

RUNI SK200 TWIN

Our SK200Twin model has a capacity of 90 kg per hour and is typically fed manually. It is recommended for an annual volume of up to 50 tons.

Read more

RUNI SK240

The RUNI SK240 screw compactor is the second largest in the EPS series and has a capacity of approximately 75 kg per hour. It can be fed manually or by conveyor. It is recommended for an annual volume of 30–50 tons.

Read moreWhich EPS densifier should I choose?

EPS comes in different qualities depending on the application and manufacturer. Density, fire retardants, and the shape of the material determine what RUNI styrofoam densifier you need.

If the EPS is wet – as is the case with used fish boxes – this also plays an important role in choosing the right solution.

Density

We have seen EPS with a density from 10 grams per litre up to 100 grams per litre. Most types are between 20-35 grams per litre. The density particularly affects the densifier's capacity per hour and whether a pre-crusher with a larger motor is required.

The Shape of the Material

RUNI continues to develop styrofoam densifiers to meet demands for the different sizes and shapes of EPS material. Through dialogue with our customers on the flow of the scrap EPS, we are constantly enhancing the possibilities of handling different types of EPS products.

Through close dialogue and collaboration with our customers, we continuously optimize the possibilities for efficient compaction – regardless of the type of EPS in question. Our experience and flexible approach ensure that you get a solution that fits your needs precisely.

RUNI EPS Compactors

Our EPS compactors are available in 5 different sizes, covering everything from smaller volumes in retail to large industrial needs.

Our smallest EPS compactor has a capacity of approx. 18 kg per hour and is typically fed manually. It is recommended for an annual volume of less than 10 tons per year. It is available with either automatic or manual jaws.

This compactor has a capacity of approximately 45 kg per hour and is typically fed manually. It is recommended for an annual volume of 10 to 30 tons. It is available with either automatic or manual jaws.

Our SK200Twin model has a capacity of 90 kg per hour and is typically fed manually. It is recommended for an annual volume of up to 50 tons.

This model has a capacity of approximately 75 kg per hour and can be fed manually or by conveyor. It is recommended for an annual volume of 30–50 tons.

Our largest stand-alone compactor for EPS has a capacity of approximately 200 kg per hour. It can be fed manually or by conveyor. It is recommended for an annual volume of 50 tons or more.

For an annual volume of over 50 tons of EPS, we also offer larger solutions, such as silo systems or twin systems.

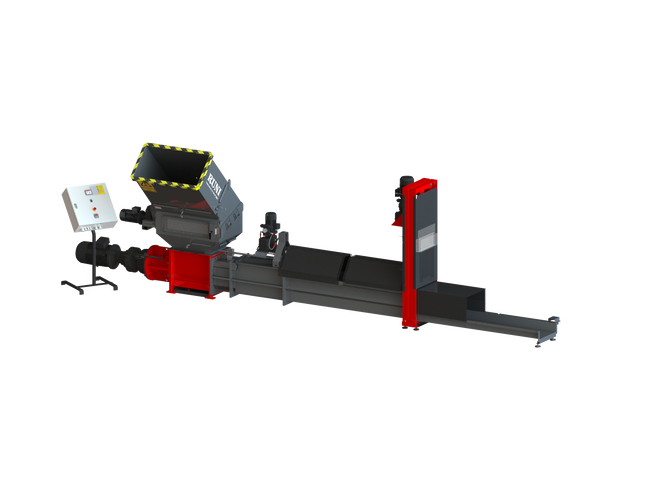

For SK240 and SK370 styrofoam compactors, a range of different hoppers, pre-crushers, silos, sensors, and block dividers are available to automatically cut the blocks. All these options are designed to optimize the workflow and adapt the solution to the desired application. Whether the system is placed at the end of a conveyor belt or integrated into your company’s internal flow, our EPS compactors ensure easy integration and optimization of the recycling process.

FAQ

What is a Styrofoam densifier?

A styrofoam densifier or EPS compactor is a machine designed for the purpose of compacting Expanded Polystyrene (EPS) foam, commonly known as Styrofoam. The screw compactor works by reducing the volume of EPS foam through compression. The compacted EPS takes up significantly less space, making it easier and more cost-effective to transport and handle for recycling purposes.

The compactor’s incorporated pre-crusher breaks down the EPS into smaller pieces, which then falls into the screw house. The screw and jaws press the air out of these pieces, reducing their size and increasing the density of the material. The resulting compacted EPS blocks or logs are more manageable for recycling facilities.

The use of EPS compactors helps address the environmental impact of EPS by facilitating its recycling and reducing the amount of space it occupies in landfills. Recycling compacted EPS contributes to sustainability and the responsible management of plastic waste.

How much can styrofoam be compacted?

The compactor reduces the volume of the EPS at a 50:1 ratio and delivers the compacted material as blocks, that can easily be managed and sold to recycling companies. The compacted blocks of styrofoam can then be recycled into polystyrene or reused for other purposes.

The volume reduction makes the transportation of the waste EPS significantly more cost-effective and contributes to more efficient waste management.

Case Studies

Xerox has achieved several benefits by compacting their EPS waste: savings on storage space, reduction in waste management costs, and revenue from the sale of compacted EPS blocks.

Read more

With an SK370 compaction system, Silkeborg Municipality annually compacts 30 tons of styrofoam, which can then be sent for recycling instead of incineration.

Read more

Every day, Morpol receives thousands of EPS boxes with fresh salmon and cooling ice. The boxes are only used once, and therefore Morpol uses the RUNI SK370 so the boxes can be compacted and sold for recycling.

Read moreContact us

If you need more information or have questions about RUNI products, please fill out the form below. We will get back to you as soon as possible.

Read more about our privacy and cookie policy.

Contact US Office

+1 (630) 422-3172

runi-us@runirecycling.com

351 Country Club Drive,

Bensenville, IL 60106