Together we turn waste to value

Powerful machinery for compaction and dewatering of many materials

Contact usTurn waste to value!

When working with RUNI you will meet a team with many years of know-how. We seek to create the best energy-efficient and long-term solution, that will make a real difference for your business and the environment.

At RUNI we think long-term, not least when it comes to our relationship with our customers. Many RUNI customers have machines that are 10-15 years old and still running well. Of course, they need maintenance and the occasional spare part replacement, but here we also strive to always offer fast and competent help – also many years after the delivery and installation of the machine.

RUNI’s screw compactors support the UN’s Sustainable Development Goals and make a positive difference that promotes sustainability and the circular economy.

Compacting waste saves space and money - and can turn waste into a valuable resource instead of a waste product. At the same time, waste handling becomes simpler and more efficient.

RUNI's screw compactors are designed for efficient compaction of a wide range of materials - from foam plastics and mineral wool to food packaging and more.

Read more about our solutions below:

RUNI's compactors efficiently separate liquid from solids. Whether you need reliable product destruction, higher calorific value of your waste, or a more efficient drying process, RUNI's screw compactors ensure an energy-efficient optimization of your process. Read more about our different solutions below:

Compacting waste saves space and money - and can turn waste into a valuable resource instead of a waste product. At the same time, waste handling becomes simpler and more efficient.

RUNI's screw compactors are designed for efficient compaction of a wide range of materials - from foam plastics and mineral wool to food packaging and more.

Read more about our solutions below:

RUNI's compactors efficiently separate liquid from solids. Whether you need reliable product destruction, higher calorific value of your waste, or a more efficient drying process, RUNI's screw compactors ensure an energy-efficient optimization of your process. Read more about our different solutions below:

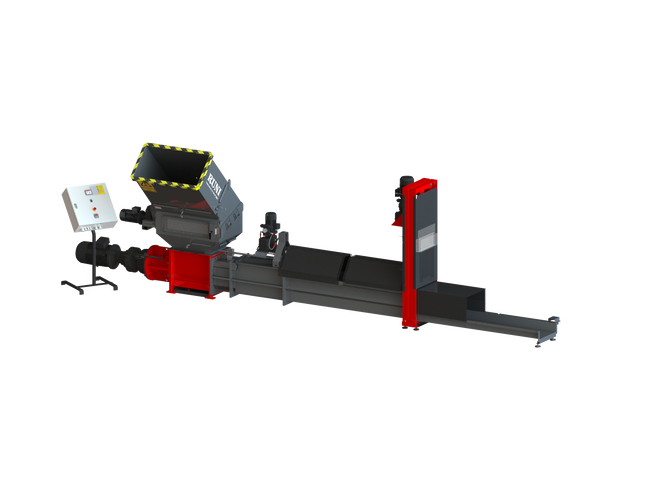

RUNI SK120

Our smallest EPS compactor, suitable for retail and small industrial businesses. It has a capacity of approx. 18 kg per hour and is typically fed manually. It is recommended for an annual volume of less than 10 tons per year. It is available with either automatic or manual jaws.

Read more

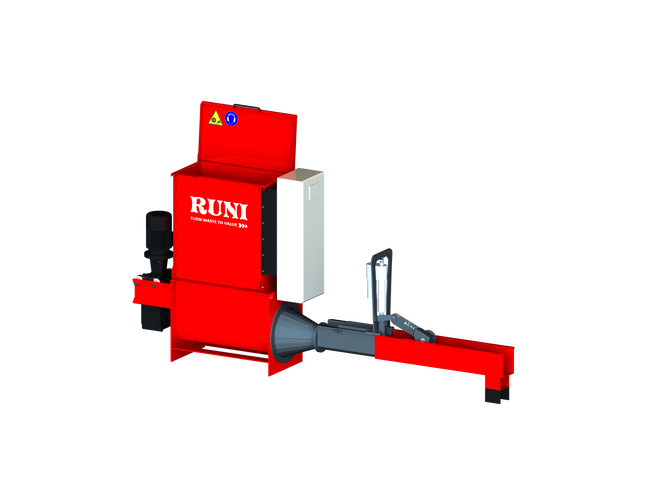

RUNI SK200

Our second smallest compactor has a capacity of approximately 45 kg per hour and is typically fed manually. It is recommended for an annual volume of 10 to 30 tons. It is available with either automatic or manual jaws.

Read more

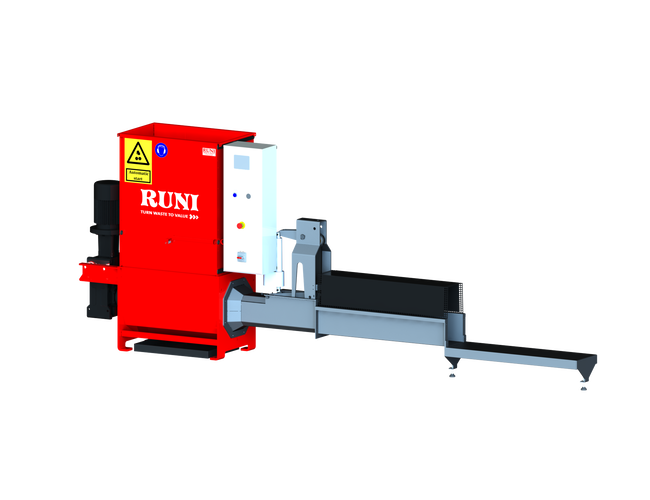

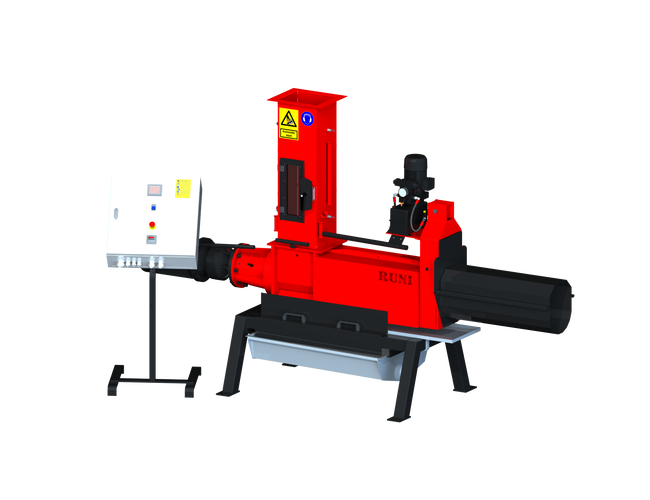

RUNI SK240 - Compaction

The RUNI SK240 screw compactor is the second largest in the RUNI range. It is capable of compacting a wide variety of materials, with capacity and output depending on the specific input.

Read more

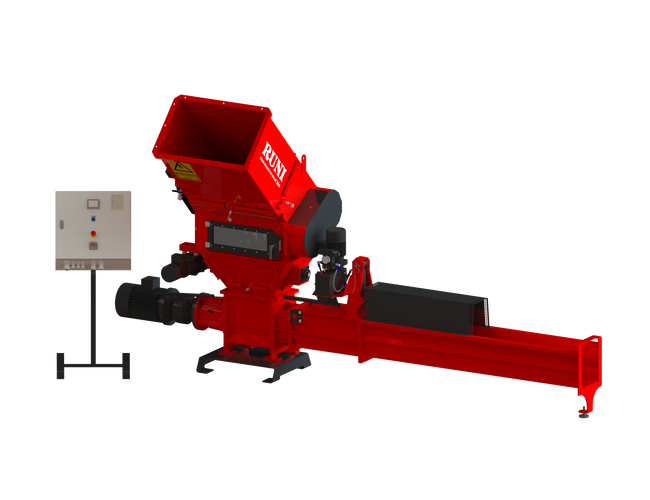

RUNI SK240 - Separation

The SK240 is our smallest dewatering machine. Capacity and output depends on the application. The machine can dewater cans, plastic bottles, and Tetra Pak, as well as dry various wet fractions such as rejects and washed PE film.

Read moreCase Studies

At Carlsberg in Fredericia, RUNI compactors empty and compact PET bottles, aluminum cans, and plastic kegs – efficiently and reliably.

Read more

One of Europe’s largest producers of plastic granulate from consumer waste chose in 2017 to replace their existing installation of screw compactors with 6 new RUNI SK370 screw compactors.

Read more

Every day, Morpol receives thousands of EPS boxes with fresh salmon and cooling ice. The boxes are only used once, and therefore Morpol uses the RUNI SK370.

Read moreCase Studies

At Carlsberg in Fredericia, RUNI compactors empty and compact PET bottles, aluminum cans, and plastic kegs – efficiently and reliably.

Read more

One of Europe’s largest producers of plastic granulate from consumer waste chose in 2017 to replace their existing installation of screw compactors with 6 new RUNI SK370 screw compactors.

Read more

Every day, Morpol receives thousands of EPS boxes with fresh salmon and cooling ice. The boxes are only used once, and therefore Morpol uses the RUNI SK370.

Read moreRUNI around the world

Our global network of distributors are all ready to discuss possible solutions to improve your waste handling with RUNI screw compactors.

RUNI around the world

Our global network of distributors are all ready to discuss possible solutions to improve your waste handling with RUNI screw compactors.

RUNI machines have enabled:

Contact US Office

+1 (630) 422-3172

runi-us@runirecycling.com

351 Country Club Drive,

Bensenville, IL 60106